Engineering precision through software solutions

Experts in software development, engineering, and consulting in robotics, logic, and systems

Contact usOfficial Representative of

Slovenia · Serbia · Croatia · Bosnia and Herzegovina · North Macedonia · Albania · Bulgaria

Project Showcase

Explore a selection of our past projects and see our expertise in action.

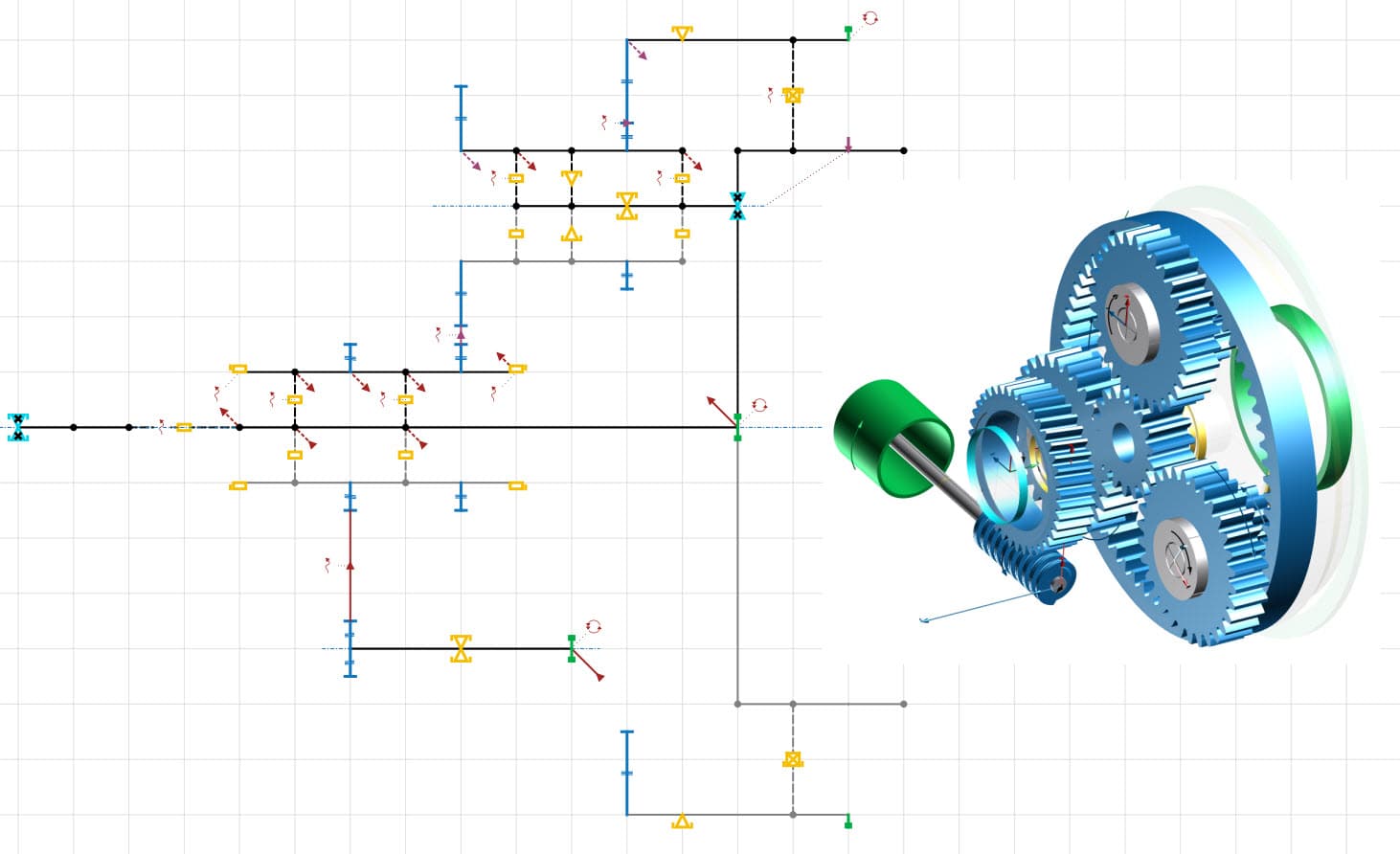

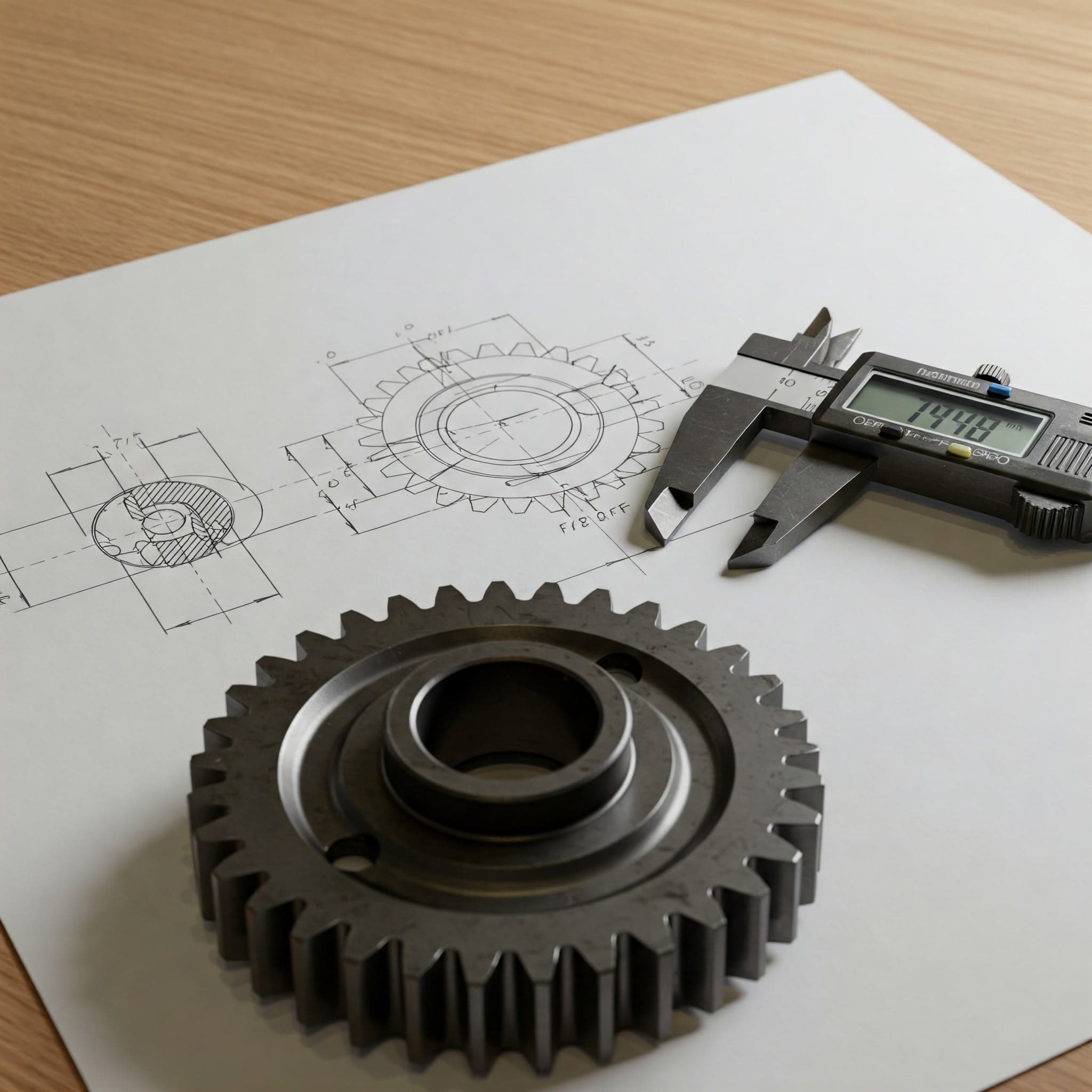

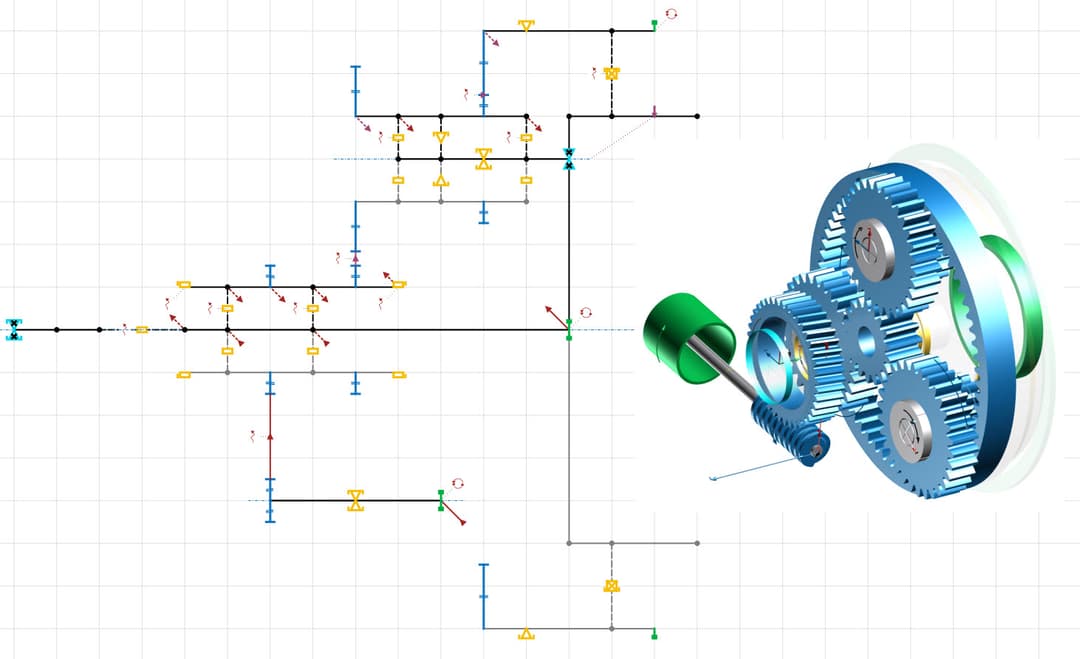

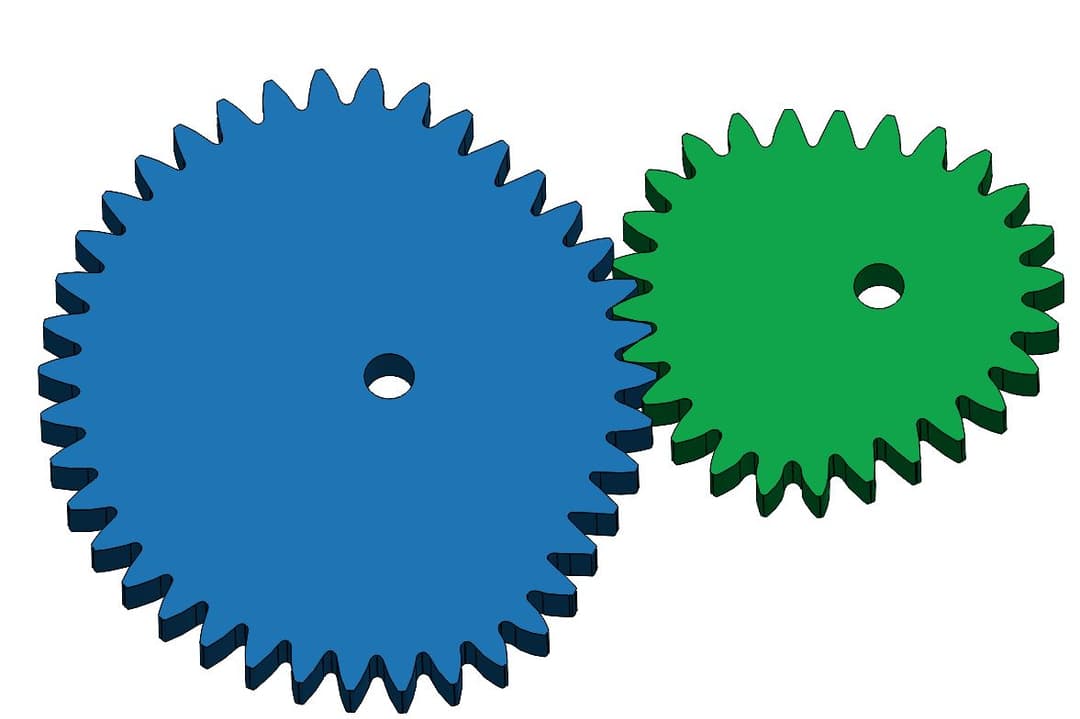

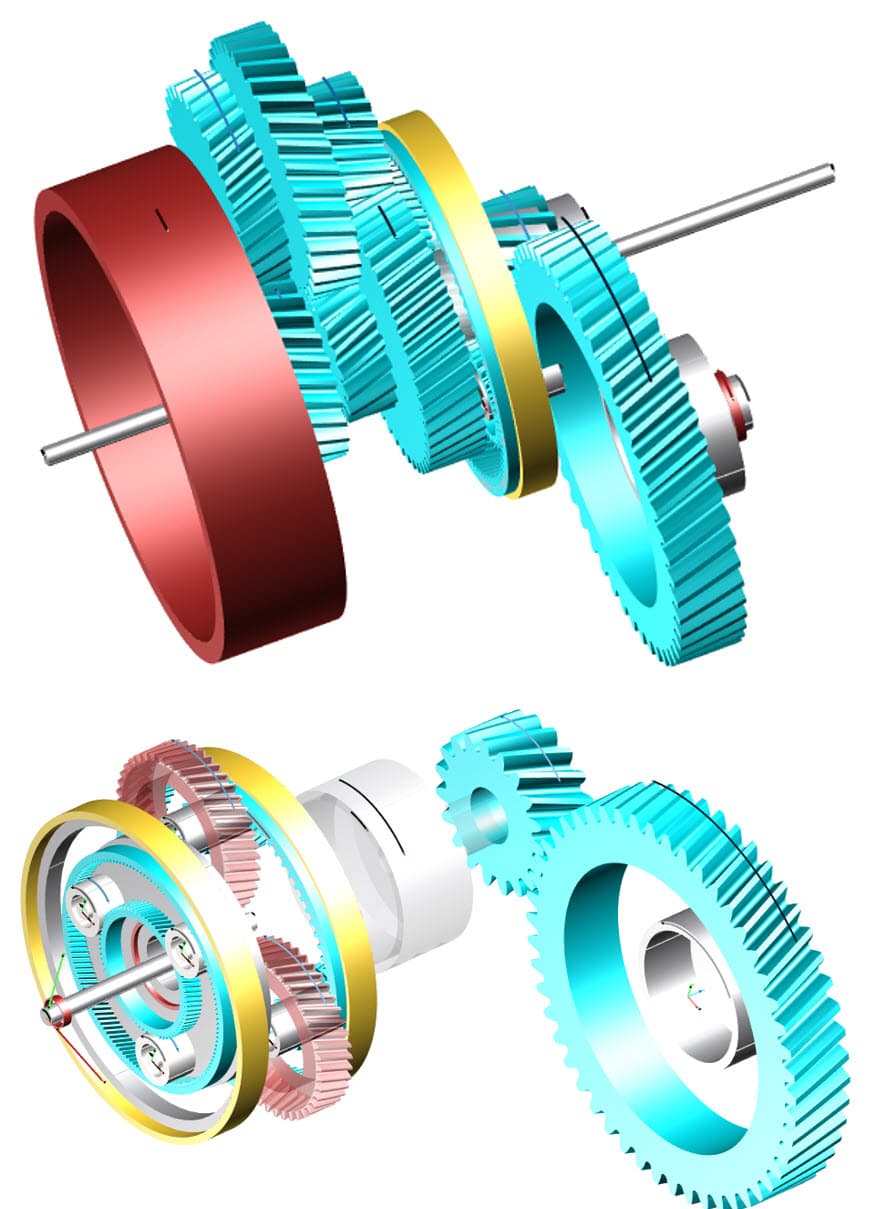

Based on different customer specifications, several gear trains for various small actuators using plastic gears were designed, analysed and optimized according to different criteria. Crossed helical worm gear pairs, cylindical gear pairs and planetary stages are usually combined to achive the desired overall transmission ratio.

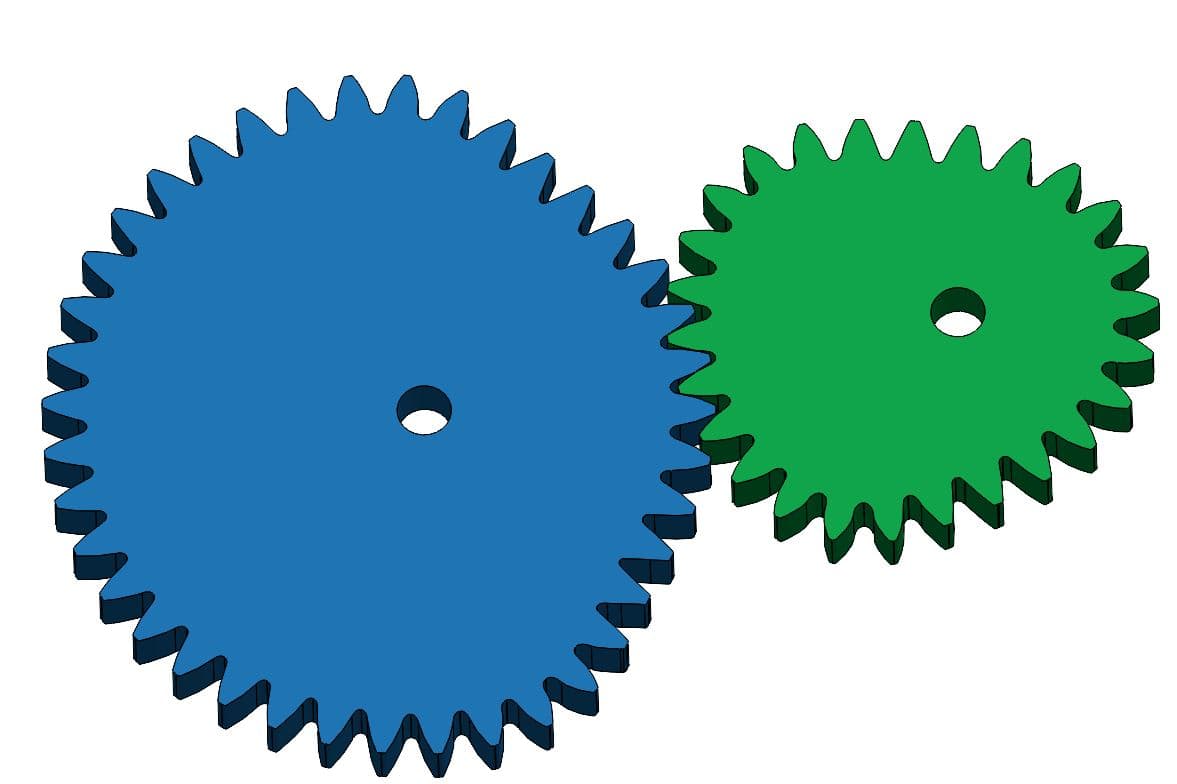

Customer requested a gear pair for steering application, having specific variable transmission ratio curve. The solution was to use the non-circular gear design, which fulfilled the required transmission ratio as well as enable continuous rotatio of the gears.

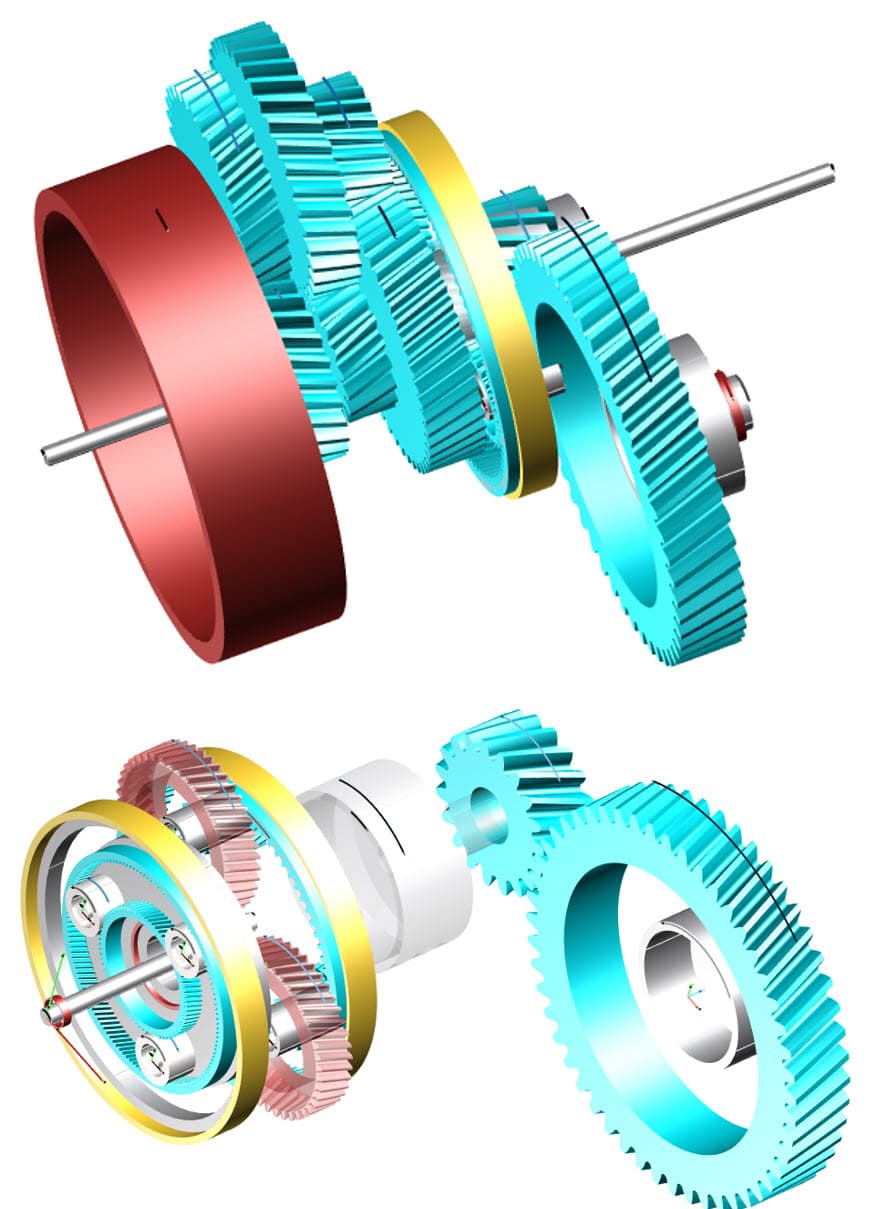

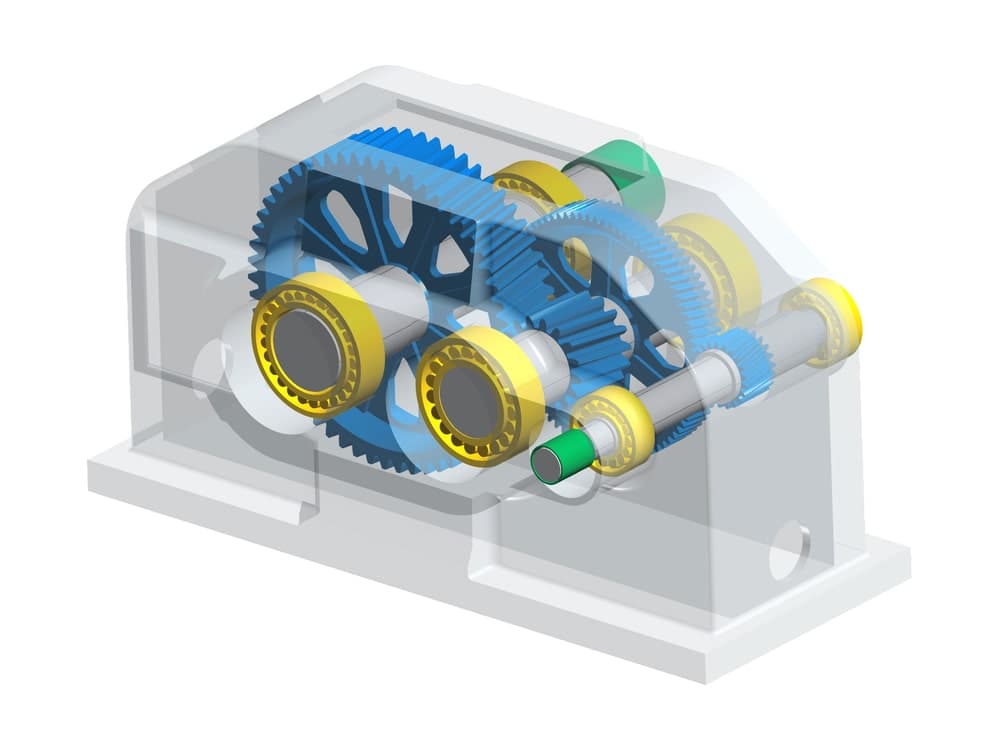

The project was part of a customer's pre-develoment project for an OEM. The goal was to combine an electric motor together with multiple stage gearbox fo fulfill the required lifetime and torque requirements. In total, more than 20 gearbox concepts were evaluated, 2 of which were selected for further detailed analysis evaluating bearings, shafts and gears.

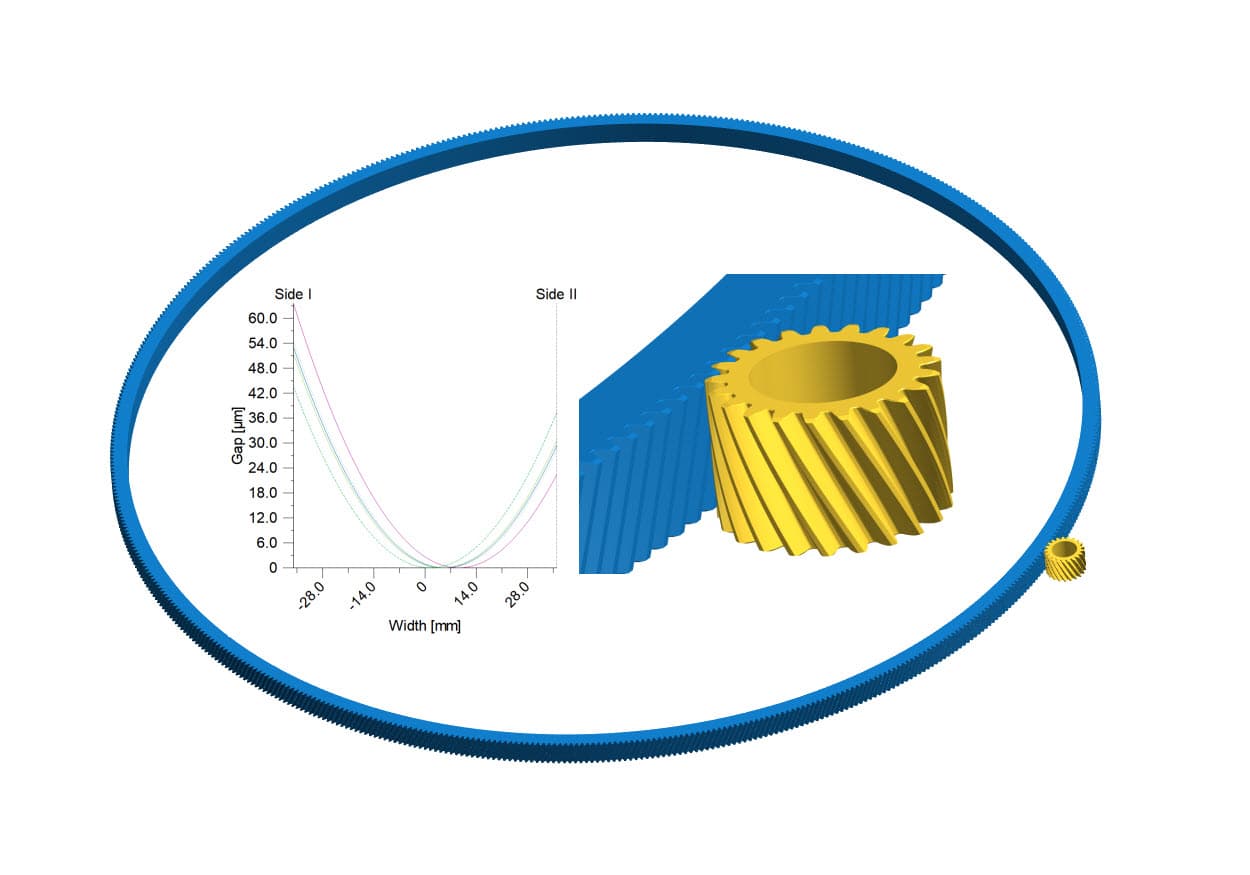

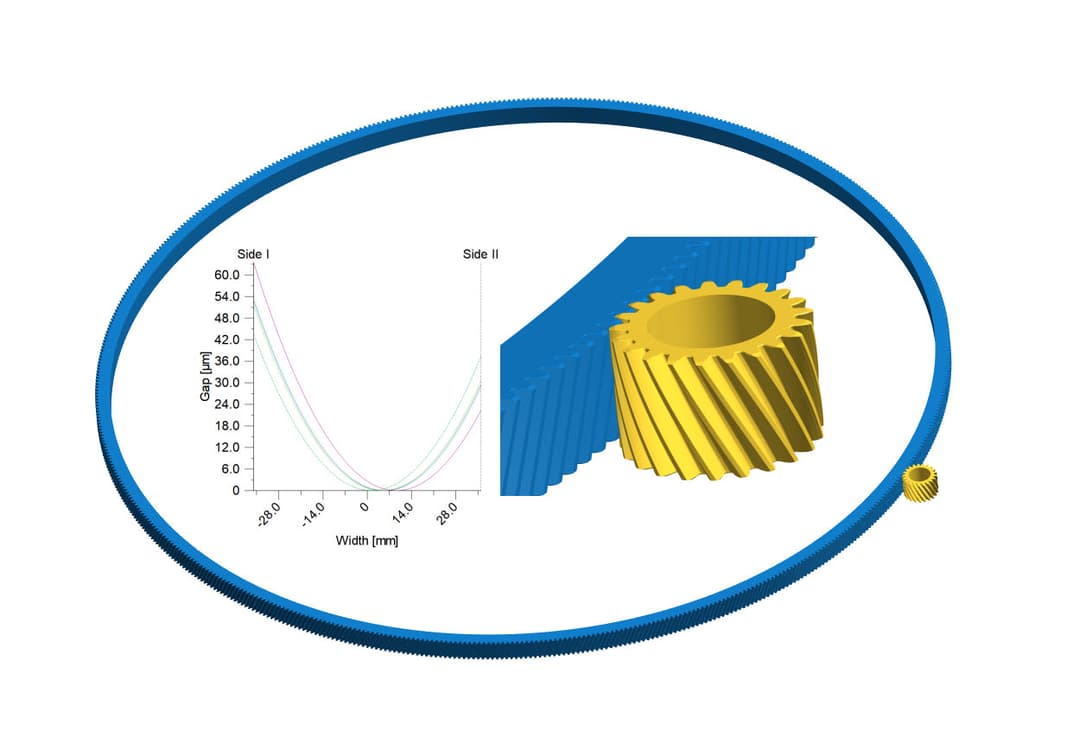

Customer had to optimise an existing gear drive for a radar antenna., because the existing design was too noisy. Considering the deformation and inclination of the pinion gear shaft, optimal profiel and flank line modifications were applied to the pinion. The task was very challenging, since the driven gear was more than 2.4 m in diameter.

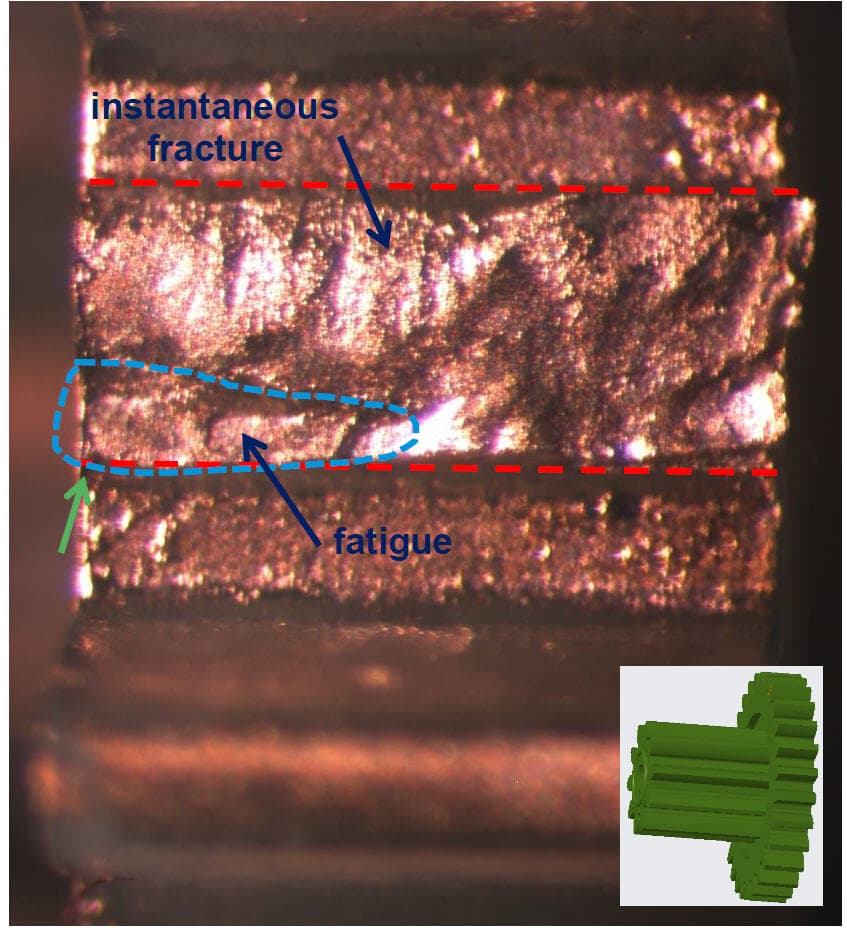

Customer had in-field failures of small plastic gears, operating in a flap actuator of a cooling application. Several actuators from the field were analyzed and the root cause of the failures were determined. The analysis consisted of actuator reverse engineering, strength calculation, SEM analysis of broken gears and tooth form optimization.

Based on old drawings or failed gears, technical documentation for the manufacturing of new gears can be created.

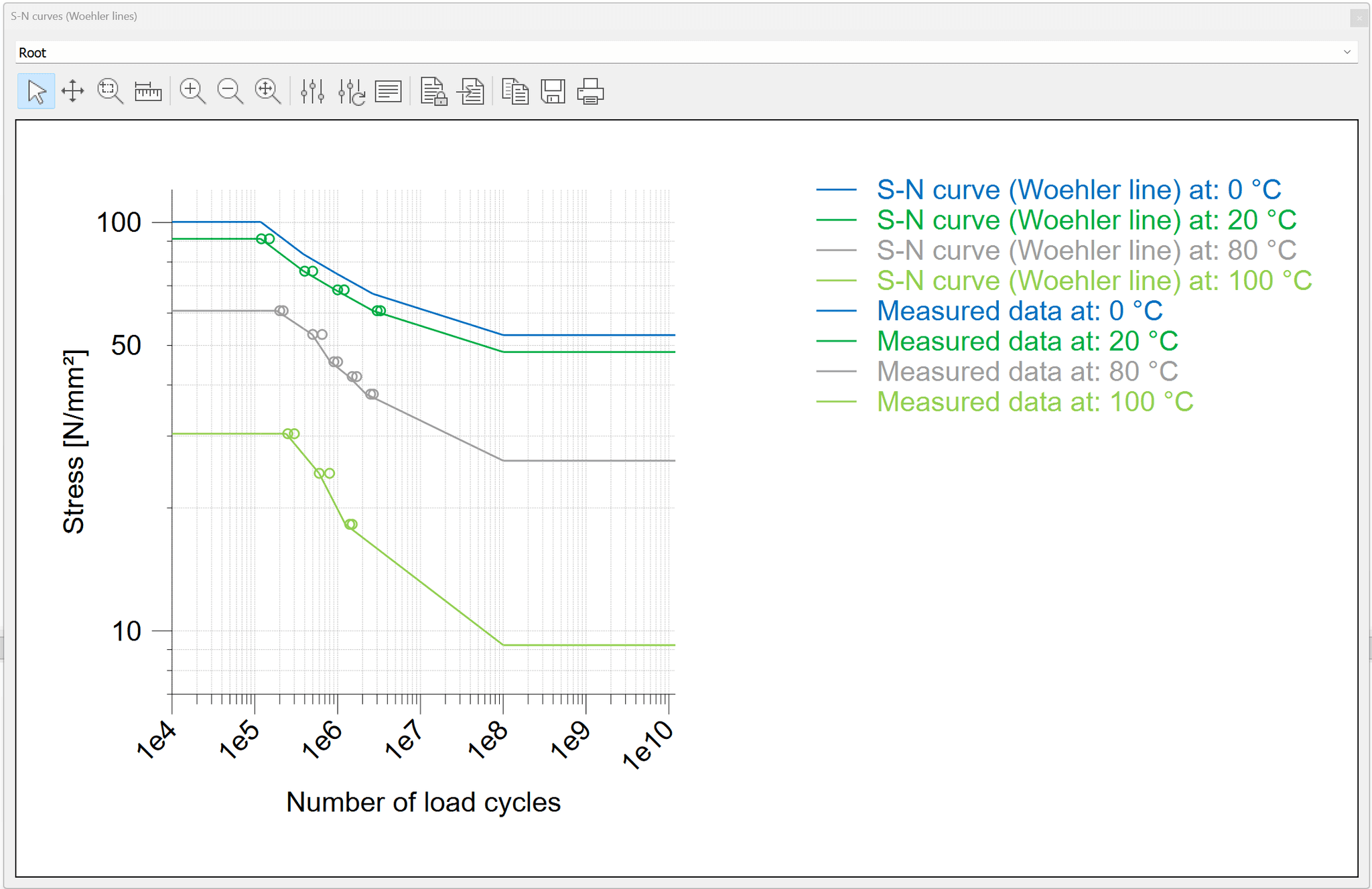

Several fatigue test rigs for plastic gears were designed and manufactured. The test rigs enable the evaluation of lifetime at controlled speed and torque at constant gear temperatures. It is possible to evaluate wear and to measure the meshing efficiencies of different material combinations under dry, grease or oil lubricated conditions.

SN curves (also known as Wöhler lines) were measured for several material manufactureres. The measured data is ready for the use in KISSsoft.

Using industrial robots for 3D printing applications with a focus on recycled polymer materials.

Services

Software Development

We develop specialized software for machine element calculations, tailored to your specific needs. Our solutions enable precise modeling and analysis of gears and gear systems.

Services

Engineering

We offer comprehensive engineering services for optimizing bearings and shafts in your mechanical systems. Our team provides expert design and verification of all key components.

Services

Consulting

Our experts advise you in selecting the best solutions for complete drive systems. With our knowledge and experience, we help you achieve optimal performance, reliability, and longevity of your systems.

Engineering Excellence in Action

Explore our innovative software solutions and engineering expertise in machine element calculations, gear modeling, and system optimization.

About Us

Bauhar d.o.o. is an engineering company based in Bled, specializing in software development for machine element calculations. We provide engineering services and consulting for gears, bearings, shafts, and complete drive systems in Slovenia and the Balkan region.

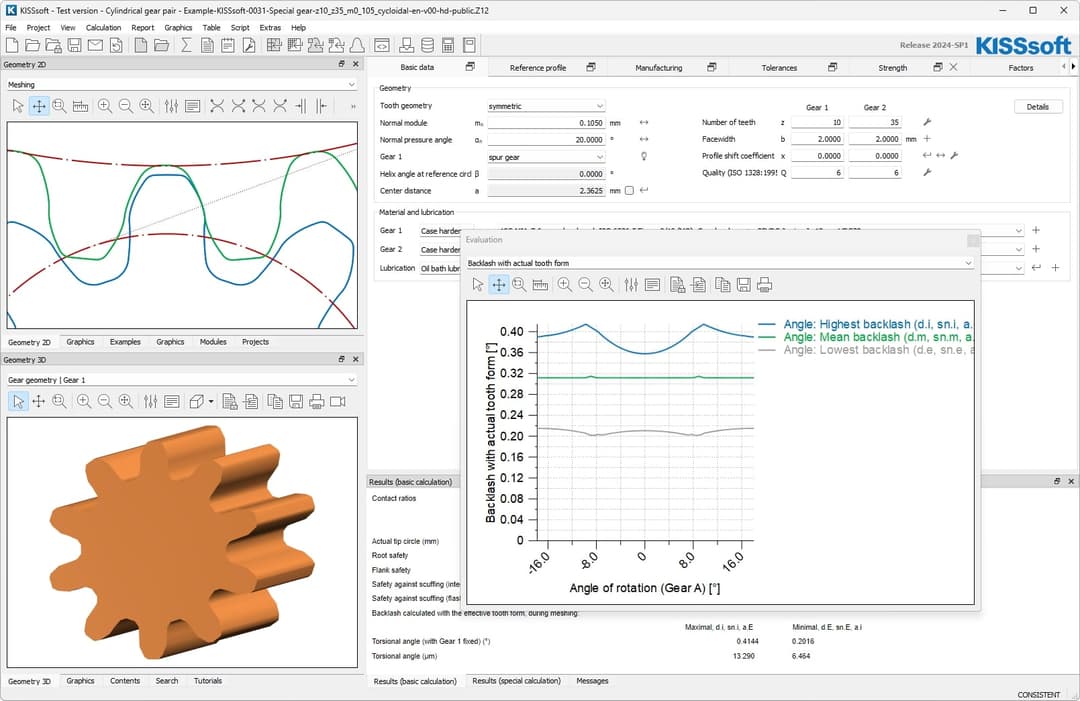

Our team combines expertise with practical experience to provide precise and efficient solutions. As the official representative of KISSsoft® software for six Balkan countries, we offer comprehensive support in implementing advanced engineering tools.

Contact

Seliška cesta 6b

4260 Bled

SI 20511230